How Much Dose It Cost To Use A Filter

This iii-part series covers research on the cost of irrigation water, including the water source and treatment with filtration and sanitation.

How much does irrigation water toll your business? The true cost is more than than just your monthly water bill. For example, well h2o includes a cost of digging the well, purchasing and maintaining a pump and electricity to pump water. In addition, if yous treat water with filtration or chlorination, these treatments must be included.

In this iii-part series, we summarize price information from growers and suppliers. We intermission down the water price into three components: (1) filtration, (2) sanitation and (3) water source. This information is helpful when choosing betwixt handling technologies. The more expensive your water source, the quicker the pay back on investment in capture and re-use of irrigation runoff.

Filtration Systems

Filtration is ordinarily needed before sanitation treatments, to remove particles that tin distribute sediment, pathogens and algae. These particles can clog irrigation lines and spread diseases. Nosotros evaluated a few of the many available filter types being used in commercial greenhouses. Examples are shown in Figures 1 through 7:

- Pressurized inline filter: pressurized water is passed through a screen filter that may be automatically or manually back-flushed. Unit tested had 100 micron pores (μm).

- Coarse static screen filter: a simple gravity- fed filter with large pore size (unit tested 400 μm) that has low operating toll and is ofttimes the first phase in filtration of ebb-and- inundation return water.

- Vibrating screen filter: gravity-fed water is passed through a screen that vibrates rapidly to motility particles to the border of the screen and unclog screen pores. Unit tested 100 μm.

- Rotating pulsate filter: gravity-fed water is passed through a rotating screen which separates water and particles, and is continually sprayed to clean the screen pores. Unit tested 89 μm.

- Fiber media ("paper") filters: gravity-fed water passes through a fabric which is indexed forward as the fabric clogs and water level backs upward. Pore size varies depending on fabric blazon and depth.

- Sand-glass media filter: pressurized water was passed through a pressurized cylinder containing crushed glass. Pore size varies depending on sand-glass particles.

- Membrane filter: pressurized h2o removes particles and ions (such equally sodium and chloride) from the water using reverse osmosis through very small pores (unit tested 0.01 μm).

Estimating the Costs of H2o Treatment

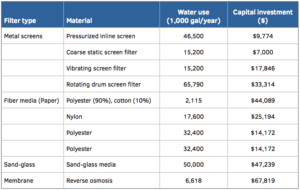

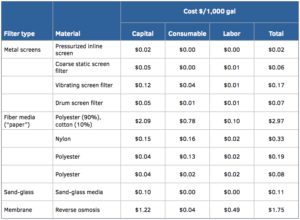

Capital and operational cost data were obtained from large commercial greenhouse operations, and were calculated per i,000 gallons of h2o filtered.

- Capital costs refer to the expenses incurred for purchase of the filtration system, shipment and installation. We applied a 10-twelvemonth linear depreciation for all filtration systems. Therefore, the capital cost per 1,000 gallons equaled the upfront investment divided by 10 (depreciation years), divided by the water volume filtered (gal), and and then multiplied by 1,000.

- Operational costs represent consumables which included filter component replacement, maintenance supplies, electricity, and labor required to run and maintain the equipment.

- Total costs represent the sum of the capital plus operational costs per 1,000 gallons of water filtered.

It is difficult to compare i filter with another based on data from commercial installations, considering of variables such as material, flow rate, make and pore size. This data should therefore be considered as examples. We recommend you undertake a similar blazon of toll assay for your ain operation after receiving price estimates from filter suppliers. We likewise do non report here the filter efficiency (percent or concentration of particles removed), just we will report that in future manufactures.

Breaking Downward the Costs

The major cost for about filters comes from the initial buy and installation (Tables one and 2). However, supply costs are pregnant for fiber media filters, because of the need to purchase rolls of material. In general, piffling labor is required to maintain filtration systems, with the exception of specialized labor required to maintain reverse osmosis systems.

Screen filters. Screen filter cost is mainly attributed to the uppercase investment, ranging from $0.02 to $0.12 per 1,000 gallons of filtered h2o (Table 2). Screen filters require very little maintenance, and operation cost is mainly electricity. Multiple inline filters can exist installed in pressurized systems with decreasing pore size to improve filter efficiency. Coarse static filters are a low cost option suitable every bit a kickoff stage of treating gravity-fed return ebb- and-alluvion water, removing large particles and improving the efficiency of a 2nd stage filter with smaller pore size and higher cost.

Fiber media ("paper") filters. These filters had the highest consumable costs, because of the need to replace fabric rolls. The capital cost of synthetic fiber filtration ranged betwixt $0.04 to $2.09 per ane,000 gallons, depending on the volume of water, and size of the filtration unit.

Costs varied widely between locations using fiber media filters. One greenhouse functioning had a filter with high capital price ($44,089) and excess capacity than the 2.1M gal of water treated. This grower also used the most expensive fiber rolls ($0.78 per ane,000 gallons) with no pre-filter. The total price for this grower to filter ebb-and-flood water was a very high $2.97 per one,000 gallons. In contrast, other operations treated significantly more water (>17.6M gal) with lower-priced cobweb media filters (<$26K, Table i). These examples emphasize the need to avert high filtration costs by matching the technology capacity to the treated h2o book.

Sand-drinking glass filters. This filter had a low operating and total toll. Sand-glass filters are often used to filter large h2o volumes, especially swimming water.

Membrane filters. Removal of very pocket-sized particles and dissolved ions from water was expensive relative to other options, and also had the highest labor to maintain the system. A loftier level of pre-filtration with other coarser particle filters upstream of a membrane filter is necessary to avoid clogging of the membrane.

Accept Home Messages

- Multiple stage filtration is generally recommended for treatment, to allow decreasing pore size with each subsequent filtration stage. Given the higher full cost of fiber media filters compared with screen and sand-drinking glass filters, fiber media filtration may be almost advisable every bit a second filtration stage following an initial screen filtration in club to reduce the consumable cost of fiber rolls.

- Sizing equipment with excess chapters increases cost. Match the capacity of irrigation technology to the catamenia rate and book in society to maximize turn a profit.

- Screen filtration systems have lower total costs per volume of water compared with synthetic fiber filtration mainly because of a lower price of consumables (electricity versus fiber rolls).

In the next issue, we will discuss nigh the cost of sanitizing water for pathogens and algae.

Acknowledgements. Thanks to funding support and collaboration from industry partner the Floriculture Enquiry Brotherhood.

How Much Dose It Cost To Use A Filter,

Source: https://gpnmag.com/article/the-cost-of-filtration/

Posted by: reimereaketury.blogspot.com

0 Response to "How Much Dose It Cost To Use A Filter"

Post a Comment